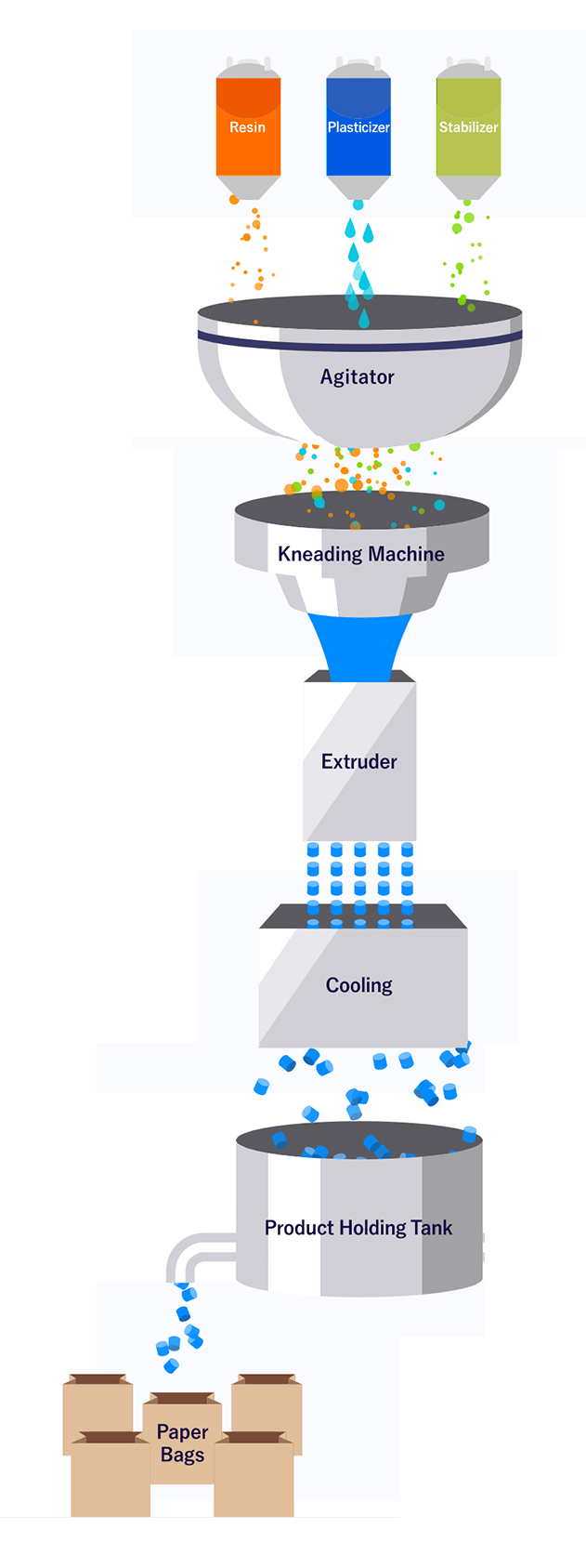

1st. Raw Material Input

Materials are added according to the professionally designed formulation base on clients’ request

2nd. Material Blending

Materials are combined and mixed in an agitator while ensuring consistency in quality.

3rd. Material Kneading

Compound is evenly kneaded with an kneading machine under respective fixed conditions.

4th. Pelletizing

Kneaded compound is formed into small granules

5th. Cooling

Pellets are cooled to stabilize shape, and then subjected to quality inspection and grading processes.

6th. Storage

Selected pellets that meet the quality standards are temporarily stored in a holding tank.

7th. Packaging

Pack compounds using different packages according to the customer’s request.

Post time: May-21-2024